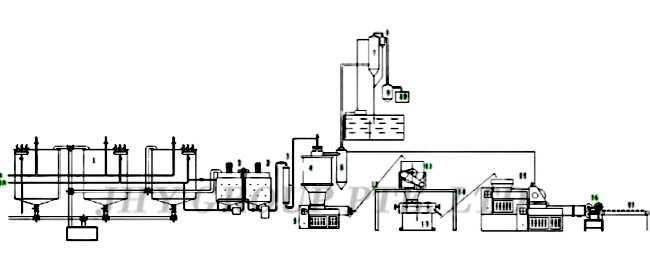

Product Name: Soap Saponification and Drying Equipment Production Line

Purpose: Used for manufacturing laundry soap or fragrant soap.

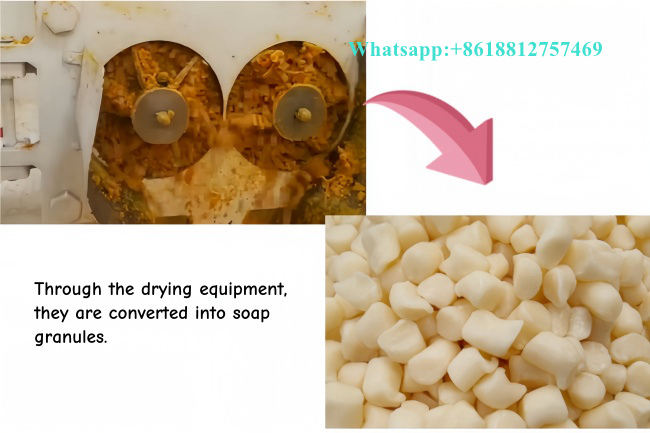

The soap dryer is a key step in making soap noodles

In industrial soap manufacturing, from the introduction of fats and oils-based raw materials to the completion of finished soap, the process comprise multiple critical technological phases, notably including saponification reaction, soap dryer and refined finishing procedures.

For 1 ton/hour production, two saponification kettles rotate—one starts as the other finishes, ensuring full raw material reaction.

This is a long-term project that involves integrating both factory floor space and workforce numbers. We have comprehensive training to teach employees machine operation, maintenance, and basic repairs, etc.

After the previous saponification step, the liquid soap solution is processed in a soap dryer to evaporate moisture and harden at low temperatures, with a moisture content typically around 15%. At the bottom, a granulator extrudes the soap flakes into soap strands.

The generated soap pellets get mixed up with other ingredients to craft soap. The saponifying bit holds significance, and formulas diverge according to kinds of fats and oils, which typically consist of vegetable oils as well as animal fats. Vegetable oils: cotton-seed oil, sunflower-seed oil, palm oil, coconut oil. Animal fats: cow fat, sheep fat, hog fat.

The details of the saponification equipment are shown above, which is made of stainless steel and carbon steel. We have a complete solution for saponification equipment. Whether you are looking to increase production or build a new factory, we have rich experience in this field.