Product name : soap making machine price

Use : produce laundry and toilet soap

Capacity : 100 -200 kg/h

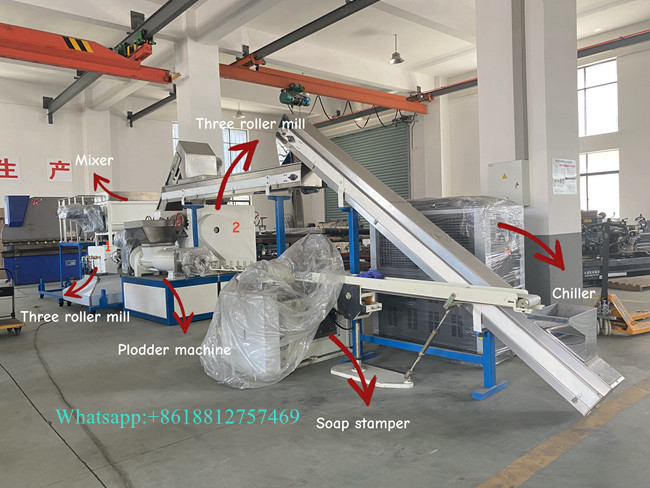

100-200kg/h automatic toilet soap making machine

The soap production line in the figure is compact. It takes less floor space than ordinary machines. The Soap Mixer and Three Roll Mill Machine are arranged in a vertical structure. Besides, this production line use two Three Roll Mill Machines. Because of this, the grinding become more fine.

Soap Mixer

The Soap Mixer adopts a double-propeller structure, which makes mixing more thorough. The materials at the bottom will be turned up for stirring, ensuring there are no dead corners.

Three Roll Mill Machine

The Three Roll Mill Machine do one thing: grind materials. After grinding, materials are scraped off by a scraper in front of the front roller. This finish the grinding process. The rollers is cast from alloy. The gap between the rollers can be adjusted through handwheels, lead screws, etc. It meet the requirements for grinding fineness.

Plodder Machine

The Plodder is a machine. It is used to extrude materials into soap bars. It adopts a double-layer shell, which is equipped with circulating cold water. This prevents materials from heating up during the extrusion process.

Stamping Machine

Automatic soap makers is really good. They give top quality, flexibility, and easy to operate.

Quality: The built-in sensor watch production. They find and fix any problem quickly. This help make sure no bad soap.

Customization: You can add different smell, color, and ingredient. This let you make soaps that fit specific customer need. You can change things fast to match what popular in the market.

Easy to Use: The control is simple. Even new operator can learn fast. Less mistake happen, so the soap always turn out same quality.