Product name : soap making machine price

Use : produce laundry and toilet soap

Capacity : 100 -2000 kg/h

Automatic toilet soap making machine

This automatic soap making machine processes soap noodles into bar soaps—laundry, multi-purpose, and toilet—with a production capacity of 100–3000 kg/h.

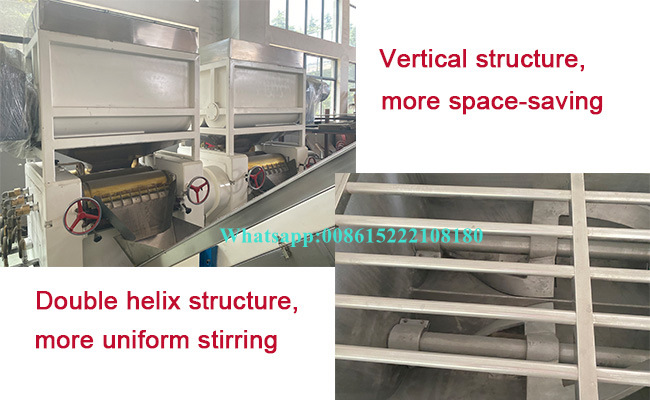

This compact automatic soap making machine adopts a vertical structure. It works well for small production sites short on space. Made of tough stainless steel, it holds up against wear and tear. The mixer, built from heavy-duty steel, comes with a protective mesh. Its dual-helix mechanism? Ensures materials blend fully and evenly every time.

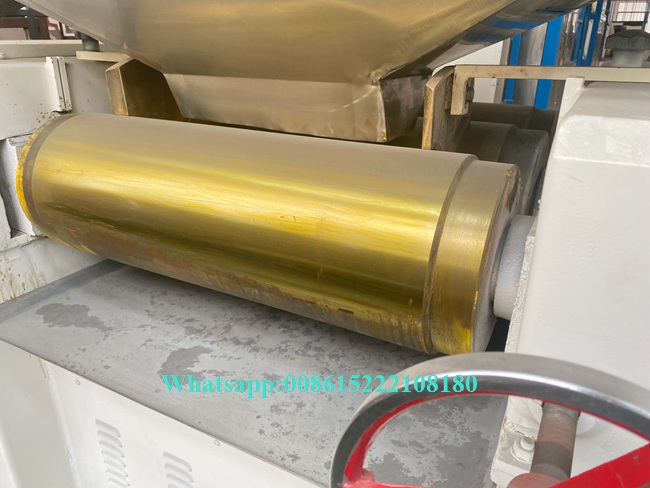

The three-roller system grinds raw materials to a precise fineness of 0.5mm, ensuring smoother textures and superior quality in the finished soap.

In automatic soap-making setups, the soap extruder sits at the heart of the shaping process. It takes properly mixed soap stock and squeezes it into steady, uniform bars—providing clean blanks for later steps like cutting and stamping. Thanks to screw extrusion tech, these bars get consistent density and tight structure, a big factor in boosting both look and quality.

Here’s a printing machine. It’s made for bath soap production. It has great customization. You can personalize soap shape and logo. To fit your brand needs.

We know customers have different production needs. That’s why we offer many printers. You can choose from them. Pneumatic or electric? One image at a time or multiple? We have the machine you need.